Shinko Sheets vs. Insulated Shinko: Which One Fits Your Project?

- 2025-06-11

- In

Introduction

When it comes to roofing and cladding solutions in Saudi Arabia, choosing the right type of sheet can make a big difference in durability, cost, and comfort. In this blog post, we compare regular Shinko Sheets with Insulated Shinko Sheets to help you decide which is best for your project.

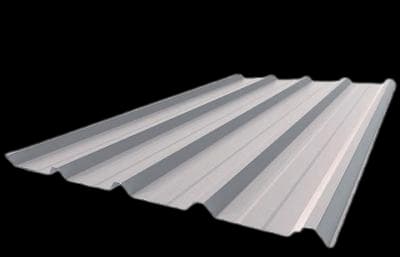

1. Regular Shinko Sheets (Zinc or Corrugated Metal Sheets)

These are single-layer metal sheets, commonly used in:

-

Warehouse and hangar roofing

-

Outdoor wall cladding

-

Carports and site shelters

Advantages:

-

Lightweight and easy to install

-

Cost-effective

-

Available in various thicknesses and colors

Limitations:

-

No thermal or sound insulation

-

May require more maintenance in hot environments

2. Insulated Shinko Sheets (Sandwich Panels)

These consist of two metal layers with an insulating core (PU or EPS foam). They're used in:

-

Cold storage rooms

-

Roofs exposed to direct sunlight

-

Buildings that need energy efficiency

Advantages:

-

High thermal insulation

-

Reduces noise transmission

-

Saves energy costs by minimizing heat gain

Disadvantages:

-

Higher upfront cost

-

Requires skilled installation

Conclusion

If your project doesn’t require thermal insulation, regular Shinko sheets are a practical and affordable choice. However, for enhanced comfort, lower energy bills, and heat protection, insulated Shinko sheets are the better investment.

At Bayt Al-Muwardooun, we supply both types with high quality, customizable options in thickness, length, and color—ensuring the perfect fit for your construction needs.

.png)